How does it work?

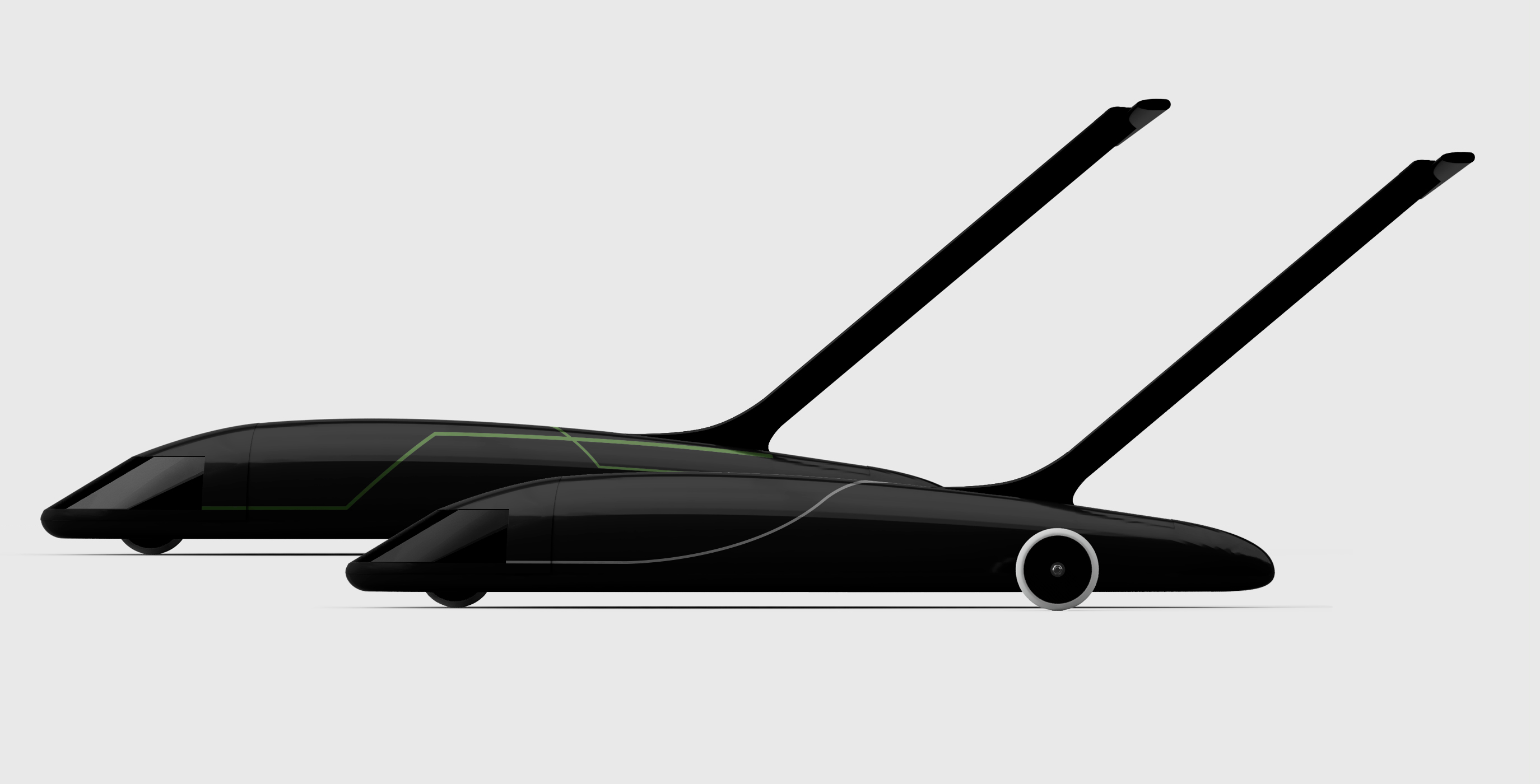

Buggy teams spend all year building, testing and perfecting their buggys, with practice races held most Saturday and Sunday mornings. The 2-day penultimate event, attended by alumni from across the country, residents of Pittsburgh, and CMU students is held every April during CMU’s “Spring Carnival” break from classes. Up to 3 buggies face off in each heat, but the overall race format is time trials with the fastest time of the weekend being crowned the champion.

Involvement

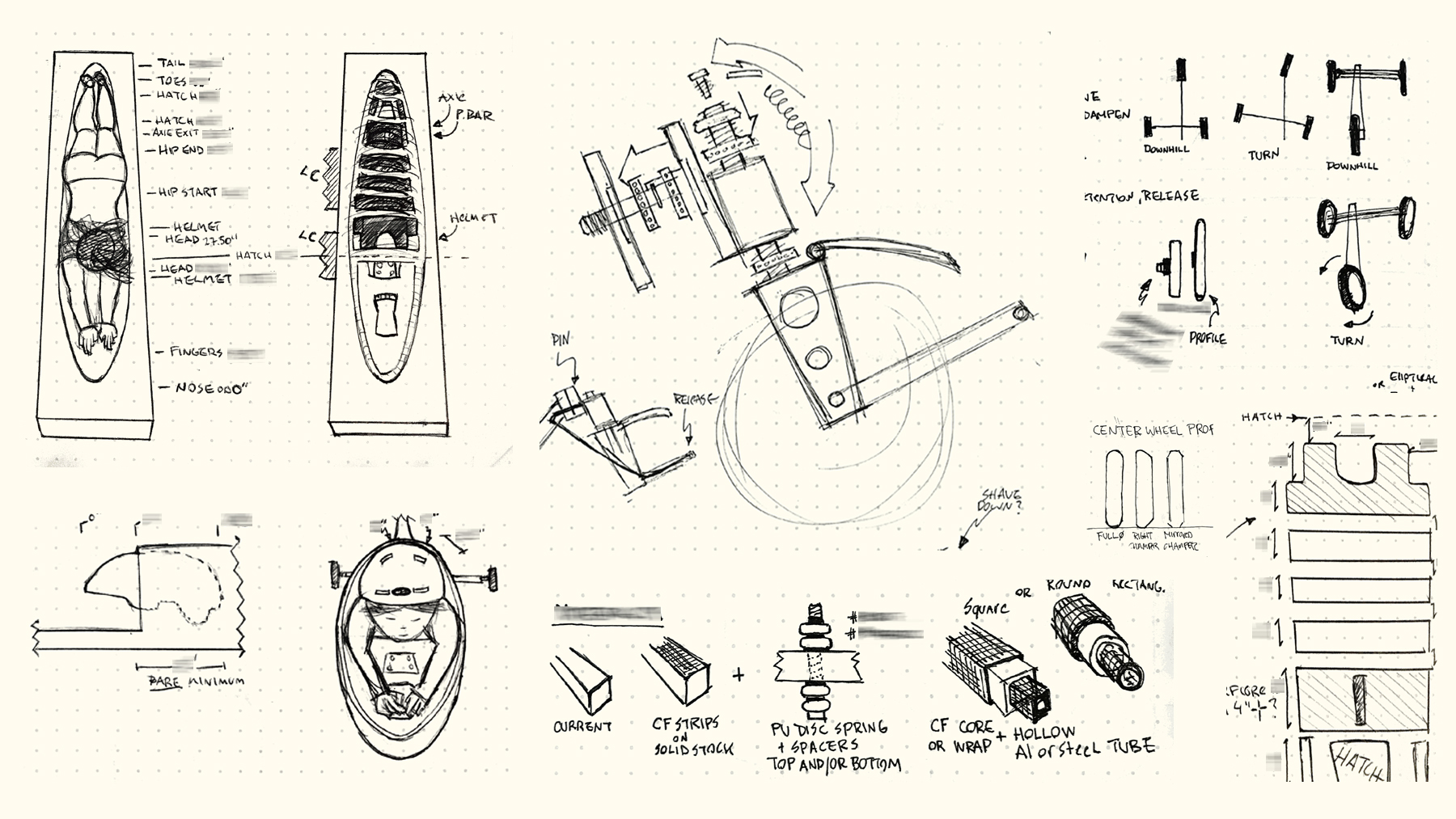

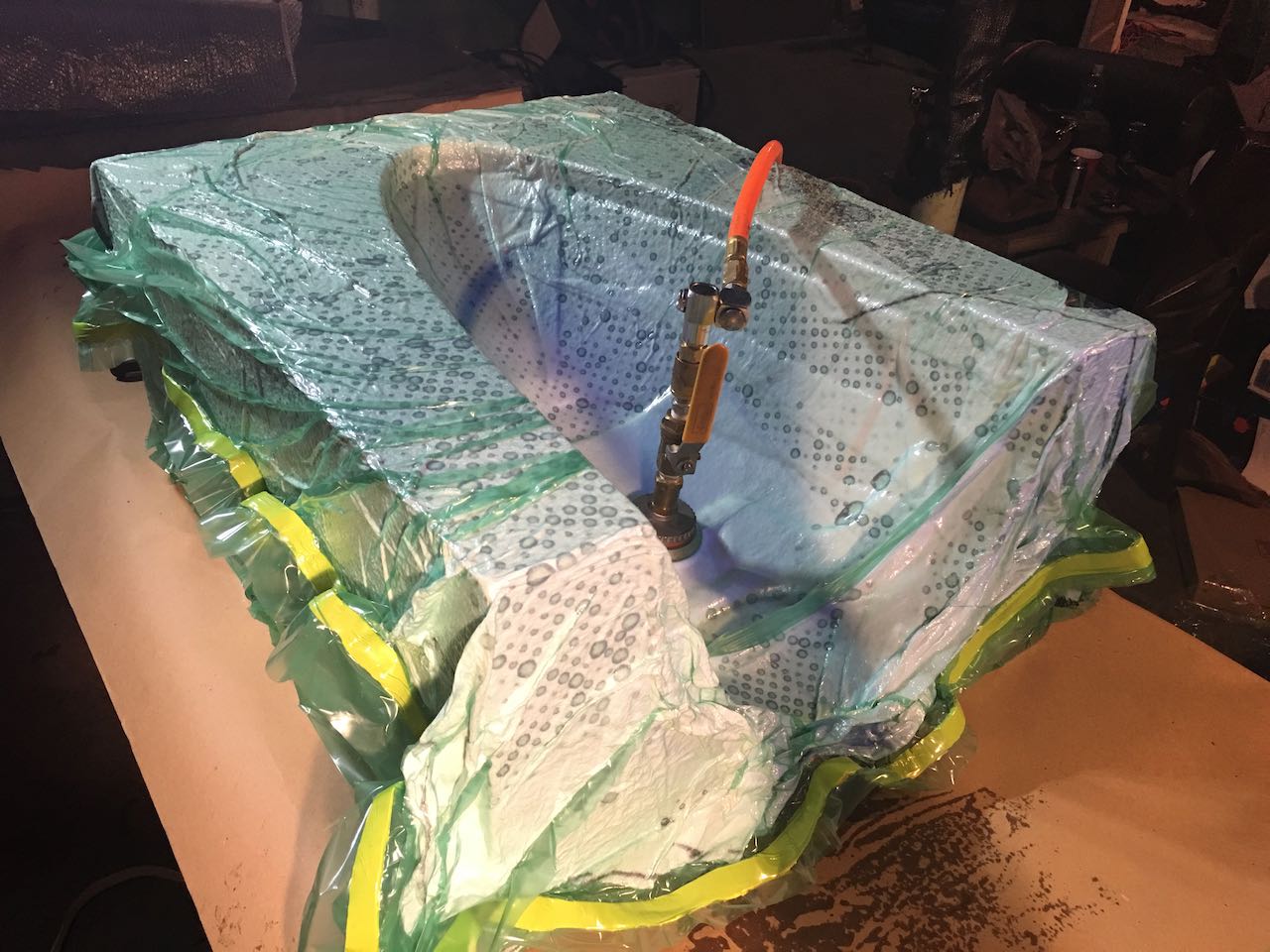

As a member of the PiKA Racing team, I was heavily involved in Buggy for 4 years. As a freshman, I learned the ropes and participated in the construction of my teams first new buggy is 3 years. The following year I served on the three person committee that organizes the races as Safety Chairman, inspecting all team's buggies to ensure they meet design, construction, and safety specifications. In my Junior and Senior years, I was elected as my team’s Captain and led the design and construction of a new buggy. Both buggys I was involved in building have gone on to win multiple trophies.