About Me

Error

Education

Experience

Design + Engineering Skills

Digital Tools

Fabrication Skills

Site designed and built by David Power ✌️

Error

Site designed and built by David Power ✌️

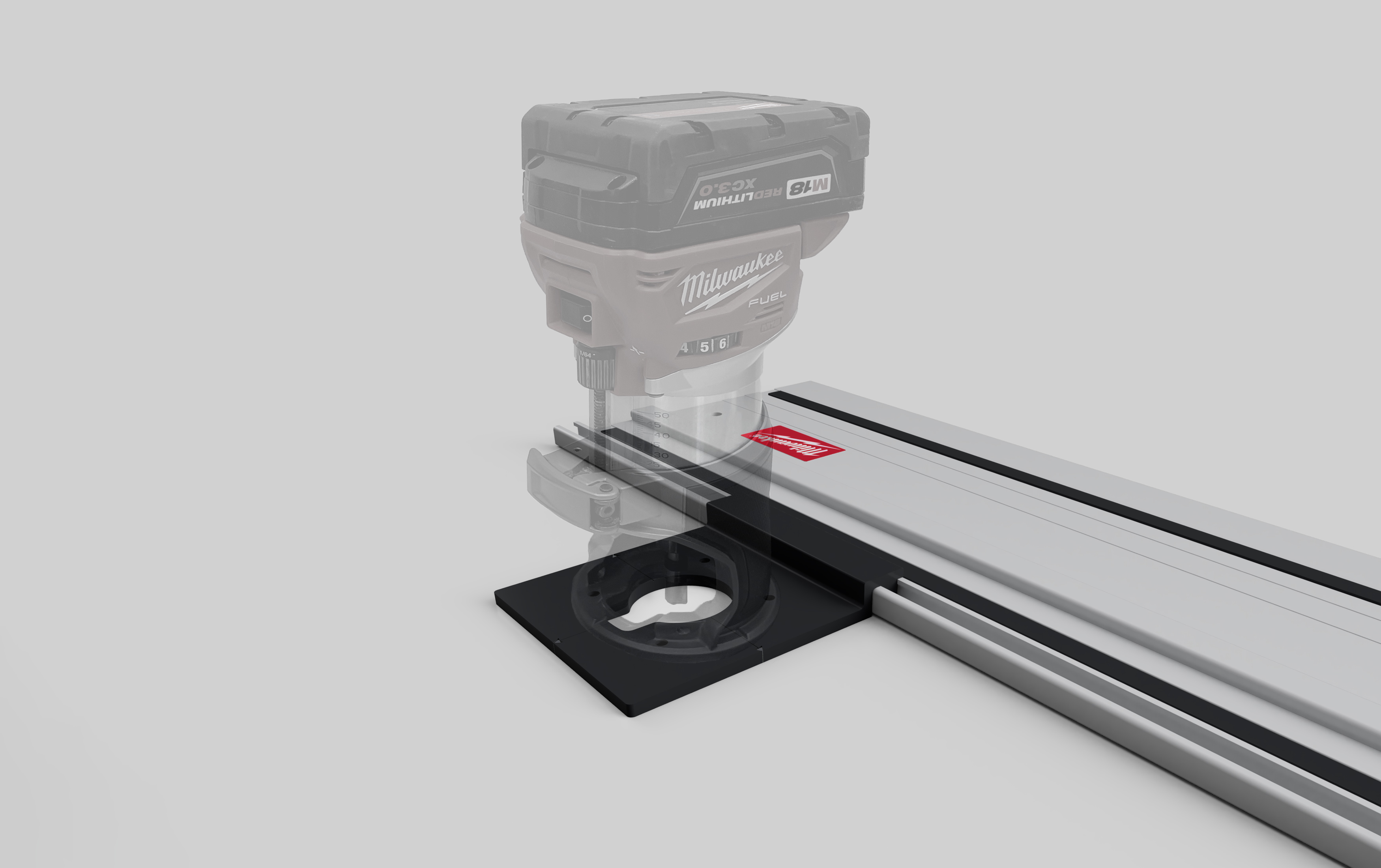

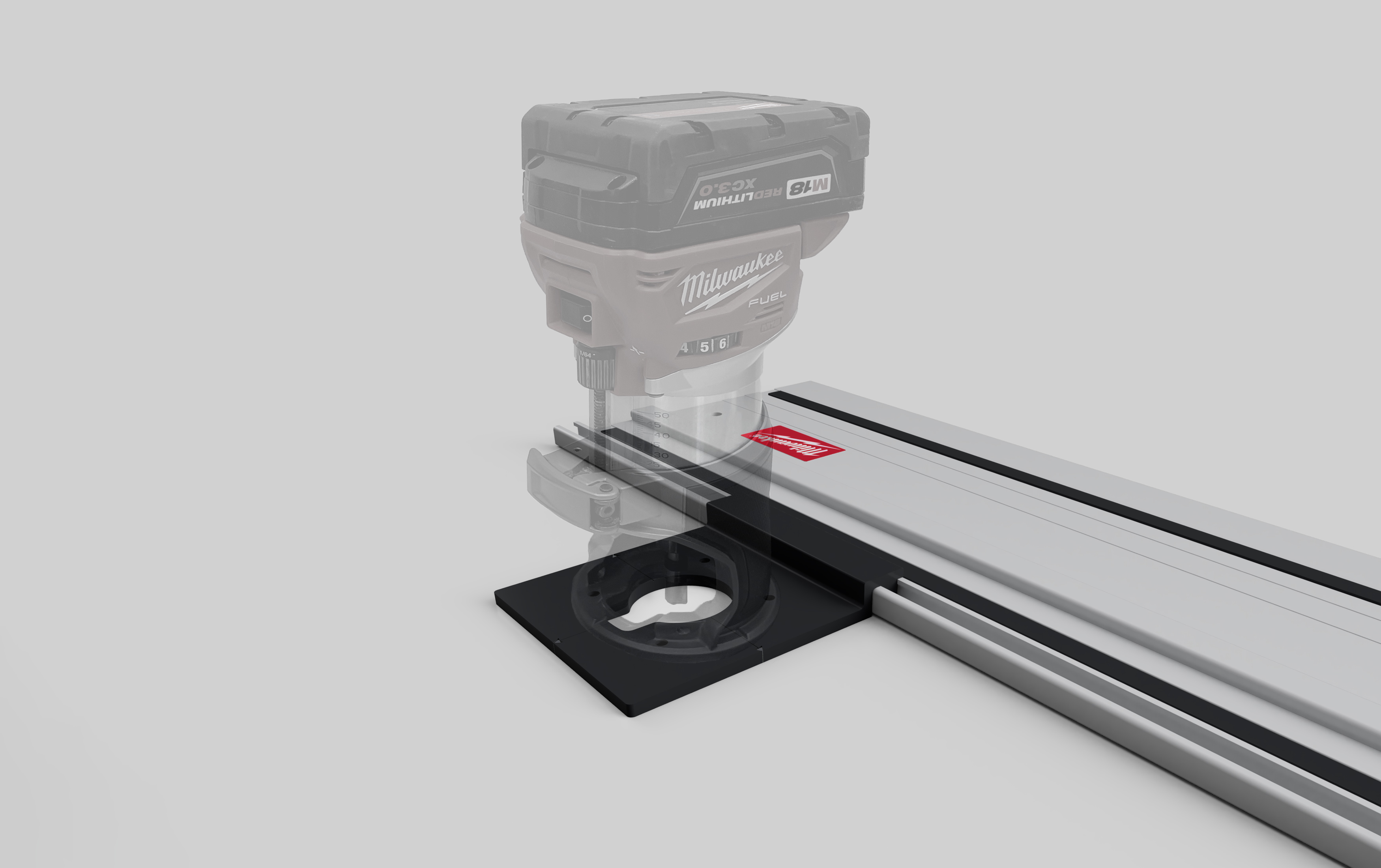

On a recent project I was presented with a uniquely challenging set of dado cuts. I realized I could probably make an adaptor to use a track saw rail to guide a router on a perfectly straight path. The result was a 3D printed adaptor plate that bolts to my trim router and rides along the t-track slot of a track saw rail. While its shape is simple, figuring out how to efficiently print it and achieve the functionality and accuracy I was after presented a bit of a challenge.

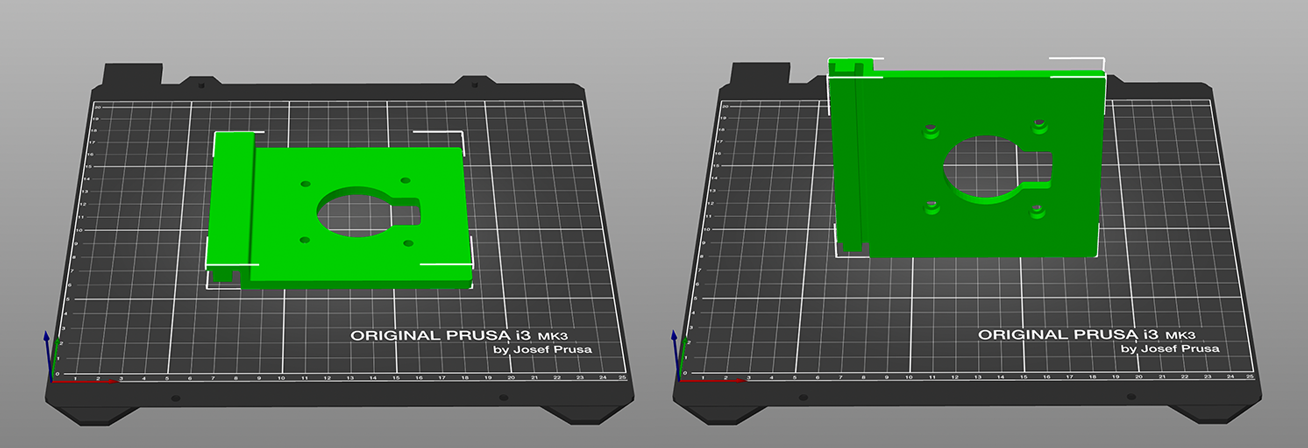

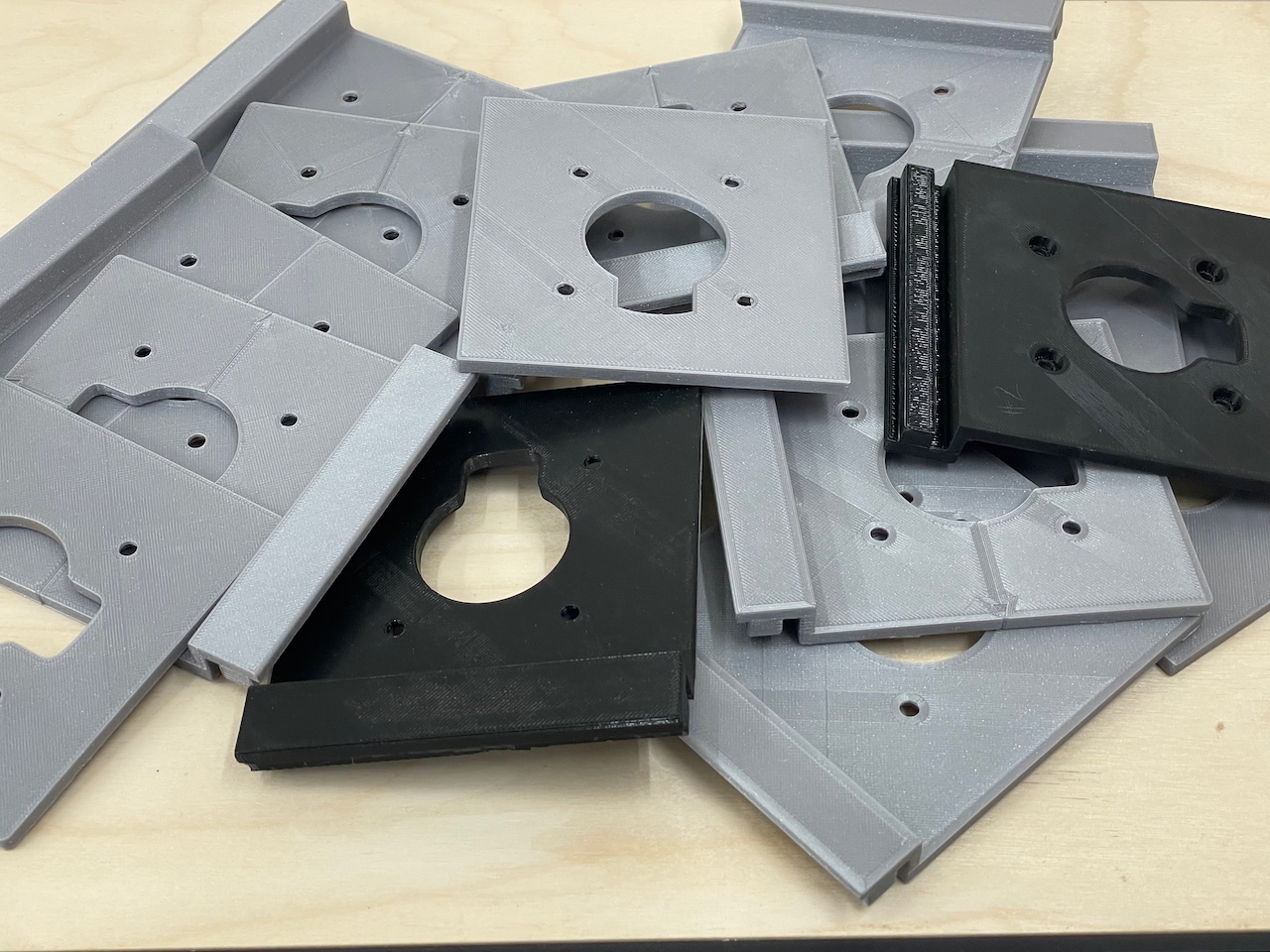

Optimizing the design for 3D printing took some trial and error. There needed to be a careful balance of tolerances tight enough to enable smooth and straight movement, while also taking into account the variances of the 3D printing process. The optimal print orientation for a smooth and clean rail profile would be vertical, but this would give the bottom of the plate a rougher finish and cause filament drooping issues in the screw holes and opening.